Innovative Concepts and Precision Solutions for Custom Molders and End Users Alike

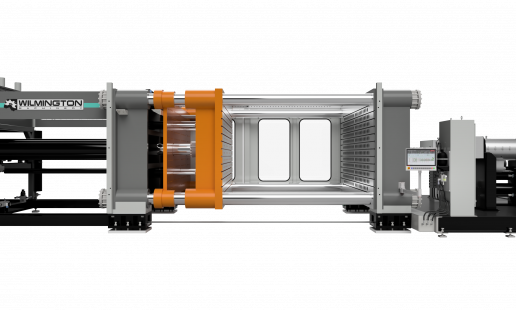

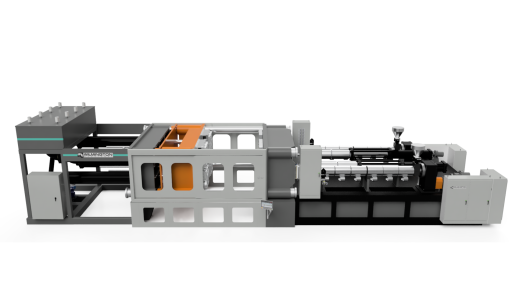

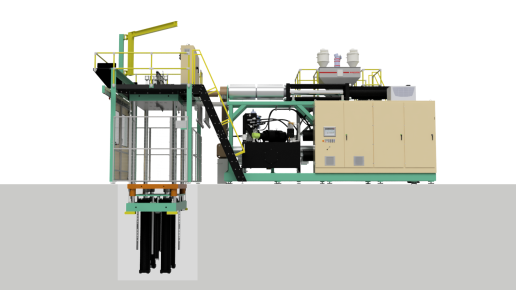

(Shown Above: LUMINA LP1000)

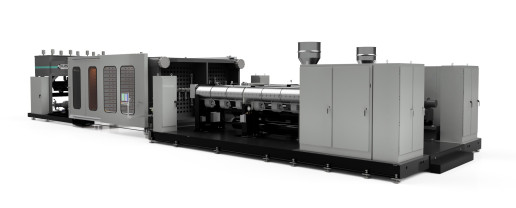

Since 1972, Wilmington has produced rotary, multi-clamp, small and large single-clamp machines with single or dual injection, in clamp capacities of 25 to 1,500 tons and injection capacities of 25 to 250 pounds.

Features and Advantages

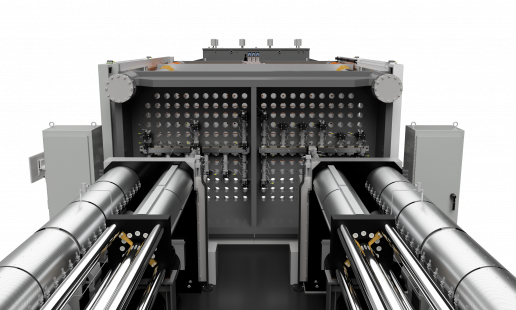

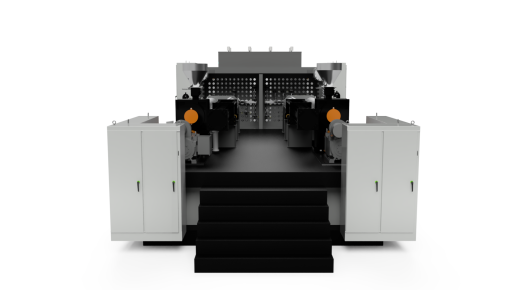

- Robust construction optimized through comprehensive FEA analysis

- 5-cylinder clamp construction for superior force distribution

- Advanced accumulator / configurable nozzle injection

- Versafil injection control of each nozzle independently

- Large platen area and more mold mounting space

- High torque extruders for fast recovery

- Open construction – ease of access for setup and maintenance

- Gas assist, counterpressure molding capabilities

History of Successes

- 1975 – Rotary Series

- 1978 – Two Station Series for Pallet Molding

- 1985 – 500 Ton Multiple Mold

- 1992 – HE Series (horizontal Elevated)

- 1999 – LP Series (low profile, robot ready)

- 2002 – LUMINA h Series

- 2006 – LUMINA LP Series

- 2009 – LUMINA Pallateer Series

- 2016 – LUMINA MP Series (medium pressure)